Effects of Technological Factors on The Properties and Structure of the Mini Oil Stick (Youtiao)

Main Article Content

Abstract

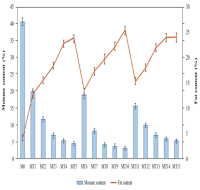

Oil stick (youtiao) is a traditional deep-fried snack widely consumed in Asia but typically produced in large sizes with a hard texture, which limits its appeal to modern consumers. This research was designed to develop a mini version of traditional youtiao through adjustments in formulation and frying conditions that improve crispness and overall quality. Particular attention was given to the role of modified starch as a partial substitute for wheat flour, the selection of suitable leavening agents, and the optimization of frying temperature and time. By examining their combined effects on texture, expansion, color, fat content, and consumer perception, the study seeks to provide a scientific approach for upgrading the conventional, handmade product into a standardized, industrially producible snack that retains traditional sensory appeal. A stepwise experimental design was employed. Modified starch (E1414) was incorporated at 0 - 15% to replace wheat flour, while three leavening systems such as 0.2% baking powder, 0.2% ammonium bicarbonate, and a 50:50 combination were tested. Frying temperatures ranged from 180 °C to 200 °C and times from 60 to 120 seconds. Statistical analysis (one-way ANOVA, p < 0.05) revealed significant effects of formulation and frying parameters on product hardness, expansion, and moisture. The final formulation, fried at 190 °C for 90 seconds, showed balanced crispness, color, and oil content (moisture 4.2%, fat 18.7%), achieving the highest sensory score (7.24/9). These findings provide a scientific foundation for industrial-scale production of high quality, modernized youtiao snacks.

Downloads

Article Details

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

How to Cite

References

1.Li G, Wu S, Zeng J, Wang L, Yu W. Effect of frying and aluminium on the levels and migration of parent and oxygenated PAHs in a popular Chinese fried bread youtiao. Food Chem. 2016; 209:123–130. Doi: 10.1016/j.foodchem.2016.04.036

2.Zhu F. Youtiao: Effect of ingredients and processing on quality attributes. Cereal Chem. 2024; 101(1):38–63. Doi: 10.1002/cche.10731

3.Bai N, Guo XN, Xing JJ, Zhu KX. Effect of freeze-thaw cycles on the physicochemical properties and frying performance of frozen youtiao dough. Food Chem. 2022; 386:132854. Doi: 10.1016/j.foodchem.2022.132854

4.Shyu YS, Hwang JY, Shen ST, Sung WC. The effect of different frying methods and the addition of potassium aluminum sulfate on sensory properties, acrylamide, and oil content of fried bread (youtiao). Appl Sci. 2021; 11(2):549

5.Saldivar SOS. Snack foods: types and composition. In: Caballero B, Finglas PM, Toldrá F, editors. Encyclopedia of Food and Health. Oxford: Academic Press; 2016. p.13–18

6.Lusas EW, Rooney LW. Snack Foods Processing. 1st ed. Boca Raton: CRC Press; 2001

7.Innova Market Insights. Snacks Market Trends 2024. Arnhem, Netherlands: Innova Market Insights; 2024

8.Innova Market Insights. Snack Trends 2025: Global Innovation and Market Insights. Arnhem, Netherlands: Innova Market Insights; 2025

9.Yang S, Zhang L, Wang X, Sun B. A review of reducing oil absorption in flour-based fried foods using wheat protein, starch, and dietary fiber: mechanisms and applications. Int J Biol Macromol. 2025; 318:144992. Doi: 10.1016/j.ijbiomac.2025.144992

10.Lima LEdM, Maciel BLL, Passos TS. Oil frying processes and alternative flour coatings: physicochemical, nutritional, and sensory parameters of meat products. Foods. 2024; 13(4):512

11.Zhu F. Influence of ingredients and chemical components on the quality of Chinese steamed bread. Food Chem. 2014; 163:154–162. Doi: 10.1016/j.foodchem.2014.04.067

12.Dana D, Saguy IS. Mechanism of oil uptake during deep-fat frying and the surfactant effect: theory and myth. Adv Colloid Interface Sci. 2006; 128–130:267–272. Doi: 10.1016/j.cis.2006.11.013

13.Subroto E, Cahyana Y, Indiarto R, Rahmah TA. Modification of starches and flours by acetylation and its dual modifications: a review of impact on physicochemical properties and their applications. Polymers. 2023; 15(14):2990

14.Chi C, Lian S, Zou Y, Chen B, He Y, Zheng M, Zhao Y, Wang H. Preparation, multi-scale structures, and functionalities of acetylated starch: an updated review. Int J Biol Macromol. 2023; 249:126142. Doi: 10.1016/j.ijbiomac.2023.126142

15.Yu B, Zheng L, Cui B, Zhao H, Liu P. The effects of acetylated distarch phosphate from tapioca starch on rheological properties and microstructure of acid-induced casein gel. Int J Biol Macromol. 2020; 159:1132–1139. Doi: 10.1016/j.ijbiomac.2020.05.049

16.Kita A, Lisińska G, Gołubowska G. The effects of oils and frying temperatures on the texture and fat content of potato crisps. Food Chem. 2007; 102(1):1–5. Doi: 10.1016/j.foodchem.2005.08.038

17.Krokida MK, Oreopoulou V, Maroulis ZB. Effect of frying conditions on shrinkage and porosity of fried potatoes. J Food Eng. 2000; 43(3):147–154. Doi: 10.1016/S0260-8774(99)00143-0

18.Krokida MK, Oreopoulou V, Maroulis ZB, Marinos-Kouris D. Colour changes during deep-fat frying. J Food Eng. 2001; 48(3):219–225. Doi: 10.1016/S0260-8774(00)00161-8

19.Penfold S. The Donut: A Canadian History. Toronto: University of Toronto Press; 2008

20.Van Hung P, Morita N. Dough properties and bread quality of flours supplemented with cross-linked cornstarches. Food Res Int. 2004; 37(5):461–467. Doi: 10.1016/j.foodres.2003.11.011

21.Peranginangin R, Fawzya YN, Sugiyono, Muljanah I, editors. Food additives and effect of thickness on fish crackers quality. In: Advances in Fish Processing Technology in Southeast Asia in Relation to Quality Management and Workshop on Compilation of Fish Products in Southeast Asia. Singapore; 1996

22.Vélez-Ruiz J, Sosa-Morales M. Evaluation of physical properties of dough of donuts during deep-fat frying at different temperatures. Int J Food Prop. 2007; 6:341–353. Doi: 10.1081/JFP-120017813

23.Pathare PB, Opara UL, Al-Said FAJ. Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Technol. 2013; 6(1):36–60. Doi: 10.1007/s11947-012-0867-9

24.Paula AM, Conti-Silva AC. Texture profile and correlation between sensory and instrumental analyses on extruded snacks. J Food Eng. 2014; 121:9–14. Doi: 10.1016/j.jfoodeng.2013.08.007

25.McDonough C, Gomez MH, Lee JK, Waniska RD, Rooney LW. Environmental scanning electron microscopy evaluation of tortilla chip microstructure during deep-fat frying. J Food Sci. 1993; 58(1):199–203

26.Roze M, Crucean D, Diler G, Rannou C, Catanéo C, Jonchère C, Le-Bail A, Le-Nail P. Impact of maltitol and sorbitol on technological and sensory attributes of biscuits. Foods. 2021; 10(11):2545

27.Abbas K, Khalil S, Meor Hussin AS. Modified starches and their usages in selected food products: a review study. J Agric Sci. 2010; 2:90. Doi: 10.5539/jas.v2n2p90

28.Sajilata MG, Singhal RS. Specialty starches for snack foods. Carbohydr Polym. 2005; 59(2):131–151. Doi: 10.1016/j.carbpol.2004.08.012

29.Mirmoghtadaie L, Kadivar M, Shahedi M. Effects of cross-linking and acetylation on oat starch properties. Food Chem. 2009; 116(3):709–713. Doi: 10.1016/j.foodchem.2009.03.019

30.Gras P, Anderssen R, Keentok M, Appels R. Gluten protein functionality in wheat flour processing: a review. Aust J Agric Res. 2001; 52:1311–1323. Doi: 10.1071/AR01068

31.Brodie J, Godber J. Bakery processes, chemical leavening agents. In: Kirk-Othmer Encyclopedia of Chemical Technology. Hoboken, NJ: Wiley; 2007

32.Neeharika B, Suneetha WJ, Kumari BA, Tejashree M. Leavening agents for food industry. Int J Curr Microbiol Appl Sci. 2020; 9:1812–1817. Doi: 10.20546/ijcmas.2020.909.227

33.Saeleaw M, Schleining G. Effect of blending cassava starch, rice, waxy rice, and wheat flour on physicochemical properties of flour mixtures and mechanical and sound emission properties of cassava crackers. J Food Eng. 2010; 100(1):12–24. Doi: 10.1016/j.jfoodeng.2010.03.020

34.Thanatuksorn P, Pradistsuwana C, Jantawat P, Suzuki T. Oil absorption and drying in the deep-fat frying process of wheat flour-water mixture, from batter to dough. Jpn J Food Eng. 2004; 6:143–149. Doi: 10.11301/jsfe2000.6.143

35.Krokida MK, Oreopoulou V, Maroulis ZB, Marinos-Kouris D. Effect of osmotic dehydration pretreatment on quality of french fries. J Food Eng. 2001; 49(4):339–345. Doi: 10.1016/S0260-8774(00)00232-6

36.Nourian F, Ramaswamy HS, Kushalappa AC. Kinetics of quality change associated with potatoes stored at different temperatures. LWT-Food Sci Technol. 2003; 36(1):49–65. Doi: 10.1016/S0023-6438(02)00174-3

37.Purlis E. Browning development in bakery products: a review. J Food Eng. 2010; 99(3):239–249. Doi: 10.1016/j.jfoodeng.2010.03.008

38.van Koerten KN, Schutyser MAI, Somsen D, Boom RM. Crust morphology and crispness development during deep-fat frying of potato. Food Res Int. 2015; 78:336–342. Doi: 10.1016/j.foodres.2015.09.022

Yang D, Wu G, Li P, Qi X, Zhang H, Wang X, Jin Q. The effect of fatty acid composition on the oil absorption behavior and surface morphology of fried potato sticks via LF-NMR, MRI, and SEM. Food Chem X. 2020; 7:100095. Doi: 10.1016/j.fochx.2020.100095